Before we jump into the introduction to the Automotive industry, let us understand what ‘automotive’ is and why it is one of the essential parts of our modern society.

What is Automotive?

The word automotive is derived from he Greek word – autos (self) and Latin word – motives (of motion); they mean ‘self-motion’ referring to a self powered vehicle.

Now you may ask what a vehicle is?

Before we answer that question, let us discuss one of the basic need of humankind since the dawn of time – Transport.

Transportation is the movement of people, animals, and goods from one location to another.

So, man invented the machine that fulfils this basic need of transportation known as vehicle.

Before the invention of wheels, however, humans used animals for transport. Horses were used extensively in transportation and as cavalry units during wars. Elephants were used to carry people in the jungles and used for warfare. Camels are still in use in deserts. In the hills, yaks and miles are a means of transport even today. Ravens were used to send letters and urgent messages during emergencies.

With the invention of the wheel, animal-powered transport came into existence like the bullock carts, chariots, and wagons. kings used horses to draw chariots in wars. Tongas can be seen even today in Indian towns like Lucknow, Aligarh, and Agra.

With the invention of the internal combustion engine(ICE), motor vehicles came into existence. Automotive comprises these motors vehicles, which are self-propelled and commonly wheeled and that do not operate on rials(such as trains). And automotive industry is the collection of organisations responsible for setting up the standards for safety , security, ad connectivity along with the wide range of companies involve in the end-to-end process of creating these automotive vehicles, including design, development, manufacturing, marketing and selling.

Supply Chain

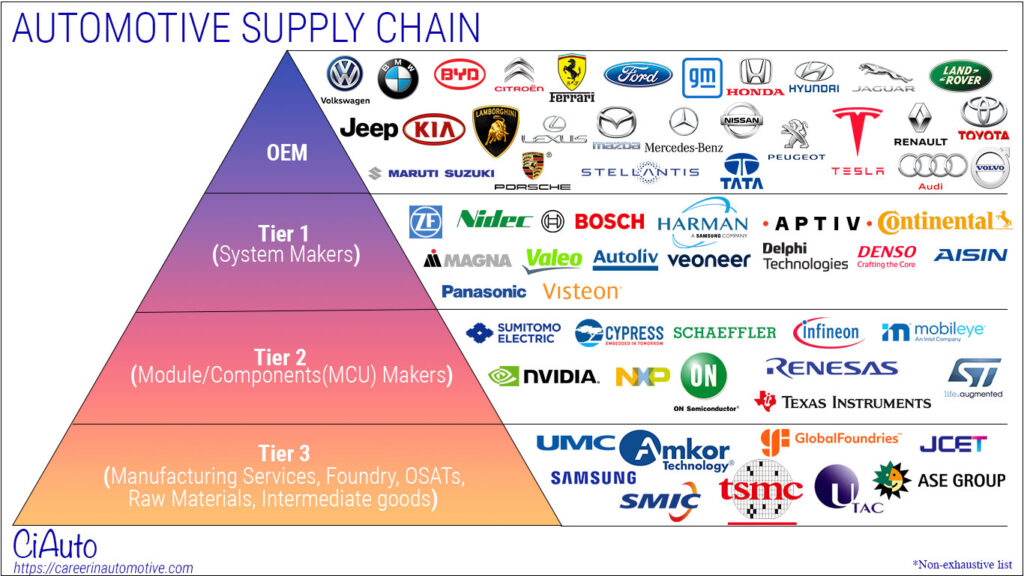

Have a look at the below illustration to glance at the automotive industry’s supply chain.

Understanding the supply chain is essential because it gives us a clear picture of which company is operating in what part of the supply chain. And if you are planning to start a career in this industry and have a specific company or skillset in mind, then this supply chain is a high-level guide to locating where you belong in this more extensive system.

OEM

Let’s deep dive into each step of this pyramid from top to bottom.

At the tip of the pyramid is the manufacturer, synonymous with OEM.

OEM stands for Original Equipment Manufacturer. In the automotive context, OEM means the manufacturer of the original equipment, that is nothing but a new vehicle(Car, Truck etc..). The parts used to construct the car are not necessarily manufactured by OEM itself. OEM often uses modules and components from its suppliers and assembles and installs them to create a vehicle of its design and features. For example, Suppose Tata uses Bosch spark plugs, Bosch fuel injectors, OSRAM headlamp bulbs, Autoliv Seatbelts and Airbags, Exide batteries, Tata Steel for body sheet metal and chassis, and Tata’s in-house Revotron petrol engine when building a car. In that case, these parts are OEM parts. Other brand parts would be considered aftermarket parts such as Blaupink infotainment systems, Champion Spark plugs, and Amaron batteries.

Suppliers (Tier 1, Tier 2, and Tier 3)

Automotive suppliers are the companies that provide goods that are used either in the production process of an automobile or become part of an automobile. At the same time, the supply of these is done either directly or indirectly to an OEM.

For example, Bosch supplies starter motors and generators, RCS ECU(Electronic Control Unit) with hardware to deploy airbags and battery technologies to the OEM directly to use as part of an automobile. On the other hand, Bosch uses automotive-grade microcontrollers and other semiconductors from companies such as Renesas, Infineon, Nvidia, and NXP to manufacture parts it supplies directly to the OEM. In this example, Bosch becomes a Tier 1 supplier while the semiconductor companies mentioned above become Tier 2 suppliers.

Thus, Tier 1 suppliers supply goods directly to the OEM, and Tier 2 suppliers provide goods indirectly to OEM via direct suppliers.

Tier 3 suppliers include semiconductor foundries (commonly called a fab) such as TSMC(Taiwan Semiconductor Manufacturing Company), Samsung Electronics, Global Foundries, and SMIC(Semiconductor Manufacturing International Corporation); Tier 3 supplier also includes OSAT(Outsources Semiconductor Assembly and Test), which are, as the name implies, the companies involved in services like semiconductor assembly, packaging and testing of ICs (Integrated Circuits). Major OSAT players are Amkor Technology, ASE Technology Holding Co., Ltd., JCET, SPIL, Powertech Technology Inc.

At the bottom of the hierarchy, Tier 2 and Tier 3 suppliers can also skip levels and supply directly to the OEM. For instance, OEMs like BMW source semiconductor chips for their in-house ECUs with proprietary technologies.